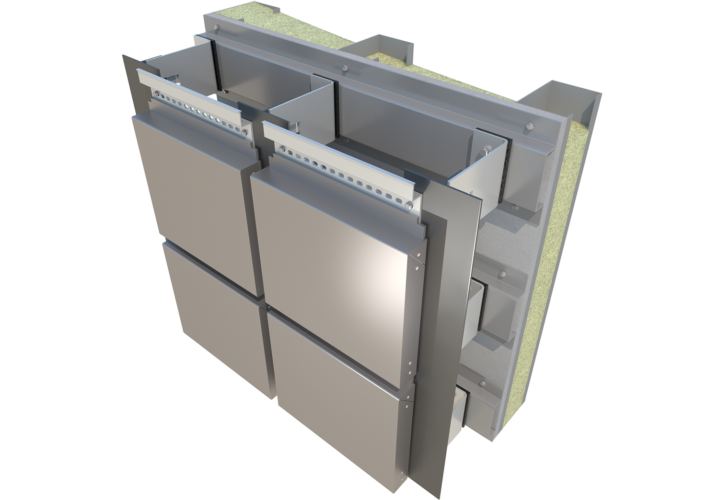

Matrix SFC Rainscreen Cladding

The Matrix SFC rainscreen system is made of pre-coated metal composite materials such as ACM, ZCM, CCM and is manufactured on our flatbed CNC machine, offering high tolerances and sharp folds. Available in a range of finishes.

This rainscreen system is available in a range of finishes and thicknesses; with fire rated cores the Matrix SFC rainscreen system is ideal for providing a flat panel in large format modular grids. The most suitable type of secondary support structure is generally dictated by the panel orientation along with the ability to incorporate thermal and floor movements where required.

Matrix SFC rainscreen systems are available in a range of materials with special features including pressings and louvres. These can be manufactured to match panels.

Benefits of Matrix SFC

- Fully tested and accredited rainscreen system to CWCT standards

- Quick and easy installation to backing structure

- Allows for a variety of colours and finishes

- Panel lengths available up to 6m

- A2 Fire Rated Material

Technical Details

Visible Material Face (Outer Skin):

Aluminium Composite Material – classified A2 rated

Finish:

PSP offer many different finishes through the use of various suppliers

Fixing:

Secret / discreet fix method

Joints:

Nominal 20mm vertical and horizontal joints

Support:

PSP Matrix T Grid system

Ancillaries:

Fixings to enable connection between bracket and rail and panel to rail by PSP. Main fix from bracket to structure will be done by others

Downloads

Fixing Details:

Matrix T Carrier System:

The “T” Rail system is probably our most popular system. Brackets are manufactured in house accommodating most cavity depths. The system is fitted vertically and best utilised where panels are horizontally laid however it but can accommodate horizontal panels with rails at each vertical joint and or the introduction of a z/top hat.

T Rail’ Secondary Support Carrier System:

Our ‘T Rail’ Secondary Support Carrier System is designed for ease of installation & versatility of use. Typical facade systems & materials may be fixed to the secondary support carrier including Honeycomb Core, Coated Aluminium, High Pressure Laminate, Timber and Zinc. Utilising our purpose developed software program we can provide structural calculations and assist with the design for each specific project, backed up with rigorous CWCT testing.

Secondary Support Grid system build-up:

When the external facade is attached to the carrier system, allowance is made for the expansion, contraction, dead load and dynamic load. Typically, rails will span from floor to floor with a break in the vertical rail where structural deflection is required.

T and L Rail:

The T and L Rail are manufactured from high quality structural grade extruded aluminium in 6000mm lengths as standard; these can then be cut to length. Both items can be supplied with a PPC finish, or a cover trim can be supplied if required. All facades are fixed directly to the face of the carrier as per the facade manufacturers’ recommendations. The versatility of the Matrix T Carrier Secondary Support Grid System allows vertically orientated facades to be attached using the CNC pressed Z rail where required.

Brackets:

Brackets are manufactured from 3mm Aluminium and consist of 3 types, supplied with a minimum arm length of 90mm in increments of 20mm upwards to 350mm. All bracket types may be fixed to varying substrates including Steel, Block Work, Concrete and Timber.

Thermal Isolator Pads:

Thermal break isolator pads may be supplied where required to your secondary support grid. They feature low thermal conductivity, optional pre-punched pads and all are manufactured from rigid PVC.

Other PSP Aluminium Systems

Curtain Walling

Windows